At the Branch of JSC "AEM-technology" in Volgodonsk (part of the Rosatom engineering division - "Atomenergomash"), the plant's specialists completed a finishing weld connecting the two halves of the reactor. This is a key stage in the manufacture of the reactor pressure vessel for the first Unit of the "Rooppur" NPP in Bangladesh.

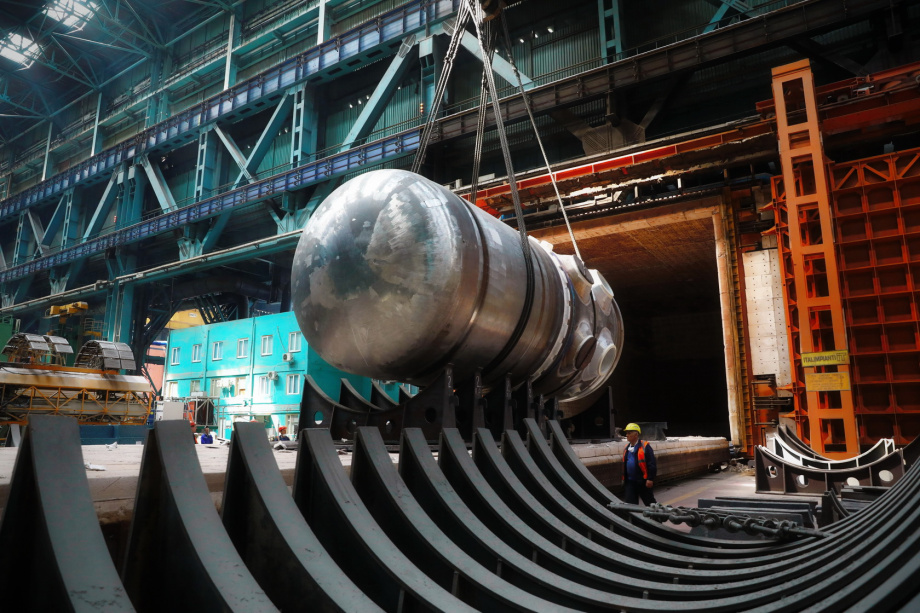

The operation lasted for 10 days with continuous heating of the weld zone - from 150 to 300 degrees. During this time, about two tons of flux and more than one and a half tons of wire with a diameter of 4 mm are used. After welding, the reactor pressure vessel weighing 320 tons is heated to 300 degrees and using a crane is transferred to the furnace, where the item will be heat treated for two days. The next stage is test operations. Specialists carry out the whole range of test measures in the weld zones: Radiographic test, Ultrasonic and Penetrant tests.

In parallel with the manufacture of the reactor pressure vessel, the plant manufactures internals for it, as well as the reactor cover and the upper unit. As of today, the vessel of the Reactor Core Barrel has been manufactured; at the final stages, a baffle and a protective tube unit.

The reactor is a first class safety item. It is a vertical cylindrical vessel with an elliptical bottom. The core and the internals are located inside the vessel. From above, the reactor is hermetically sealed by a cover with the drives of mechanisms and elements for regulating and protecting the reactors and nozzles for outputting the cables of the in-core monitoring sensors installed on it.

JSC "Atomenergomash" is a single source supplier of all equipment of the reactor compartment of the "Rooppur" NPP and a significant part of the equipment of the turbine island. Division companies manufacture Reactors, Steam Generators, Pumping and Heat Exchange equipment.

The "Rooppur" NPP is designed and constructed according to the Russian design. The plant will consist of two power units with a capacity of 1200 MW each, with WWER reactors of generation 3+.